最新消息

Auto Print Sub-board S/N

2024

Automatically print associated work order label contents to quickly address barcode data conversion and printing issues, while supporting multiple production workflow modes.

2024

Automatically print associated work order label contents to quickly address barcode data conversion and printing issues, while supporting multiple production workflow modes.

2024

For the TFT / ITO LCD panel manufacturing industry, utilizing Data Matrix ECC120 and VeriCode (0.86mm x 0.86mm) barcode reading technology to further enhance yield rates.

2024

Integrating DEK printer equipment with the Shop Floor Control System to intelligently filter out erroneous and blank data.

2023

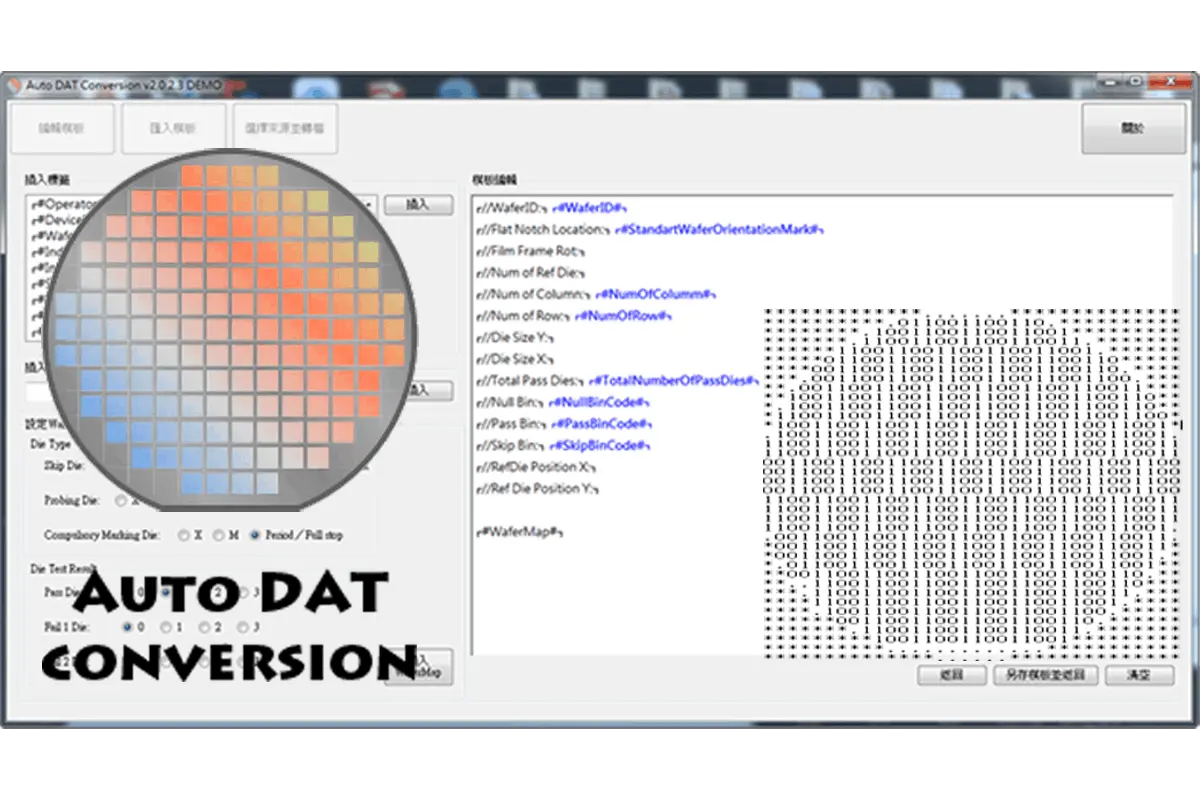

Performing MAP conversion on DAT files in semiconductor equipment to quickly resolve errors caused by inconsistent import file formats from various client devices.

2023

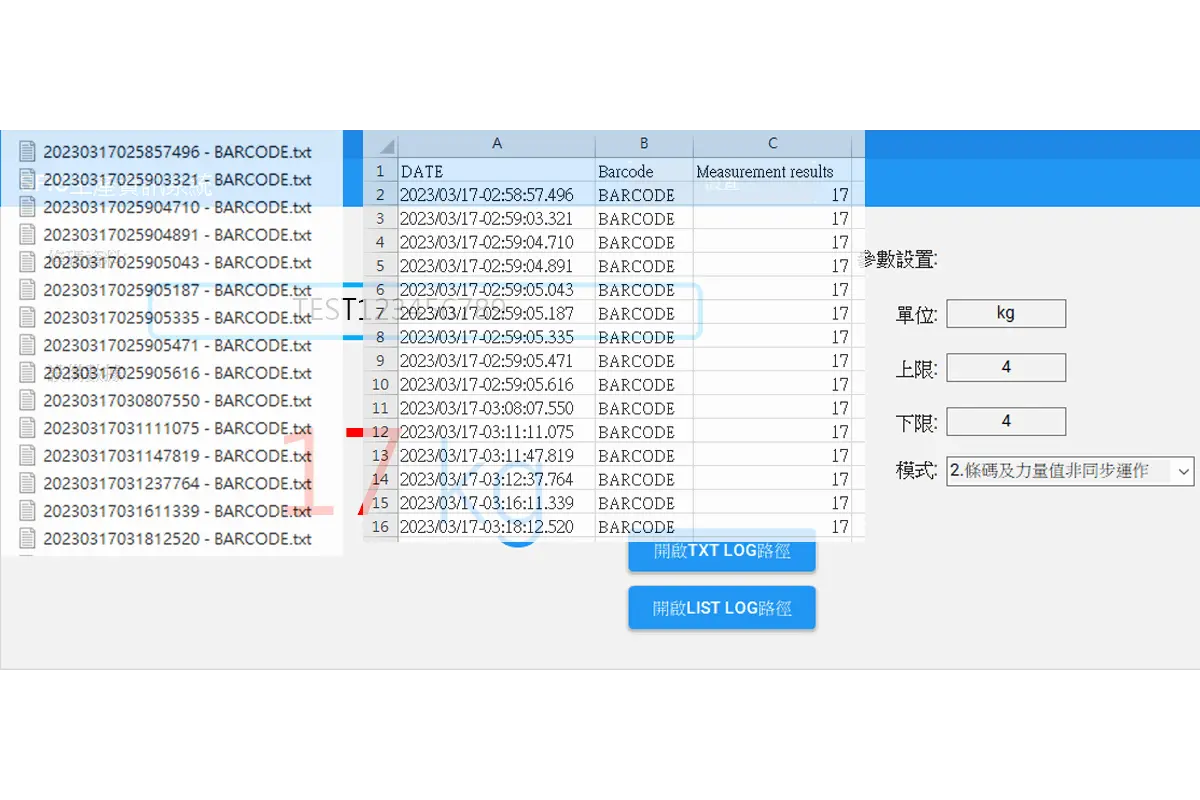

For traditional machining industries, an automated parts press machine integrates pressure data and links it with barcode information to automatically generate log files.

2023

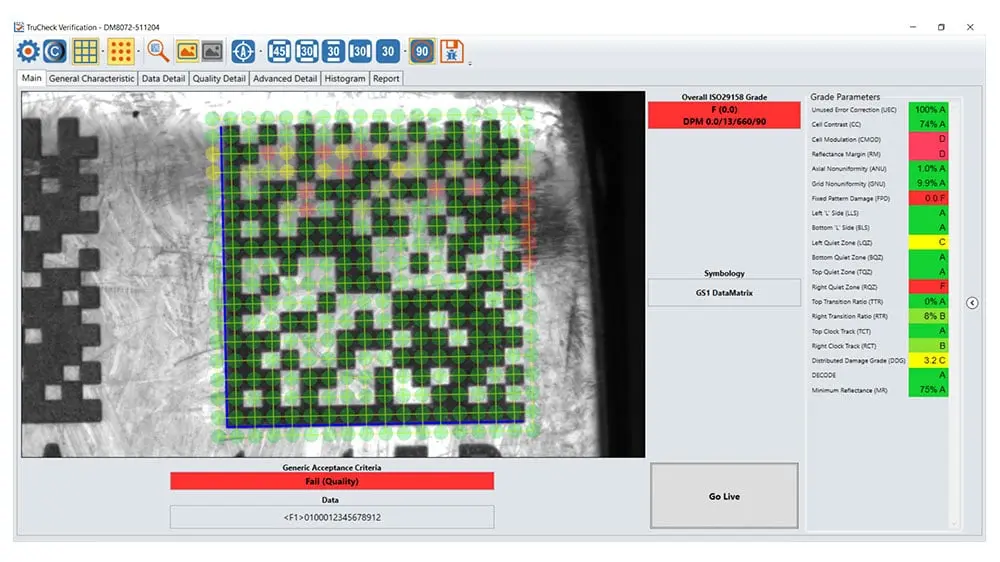

To verify the barcode quality of laser marking, ensuring it meets the highest standards.

2023

for PCB serial numbers on the bottom (BOT) side, install external barcode reader to enhance the equipment's capabilities.

2023

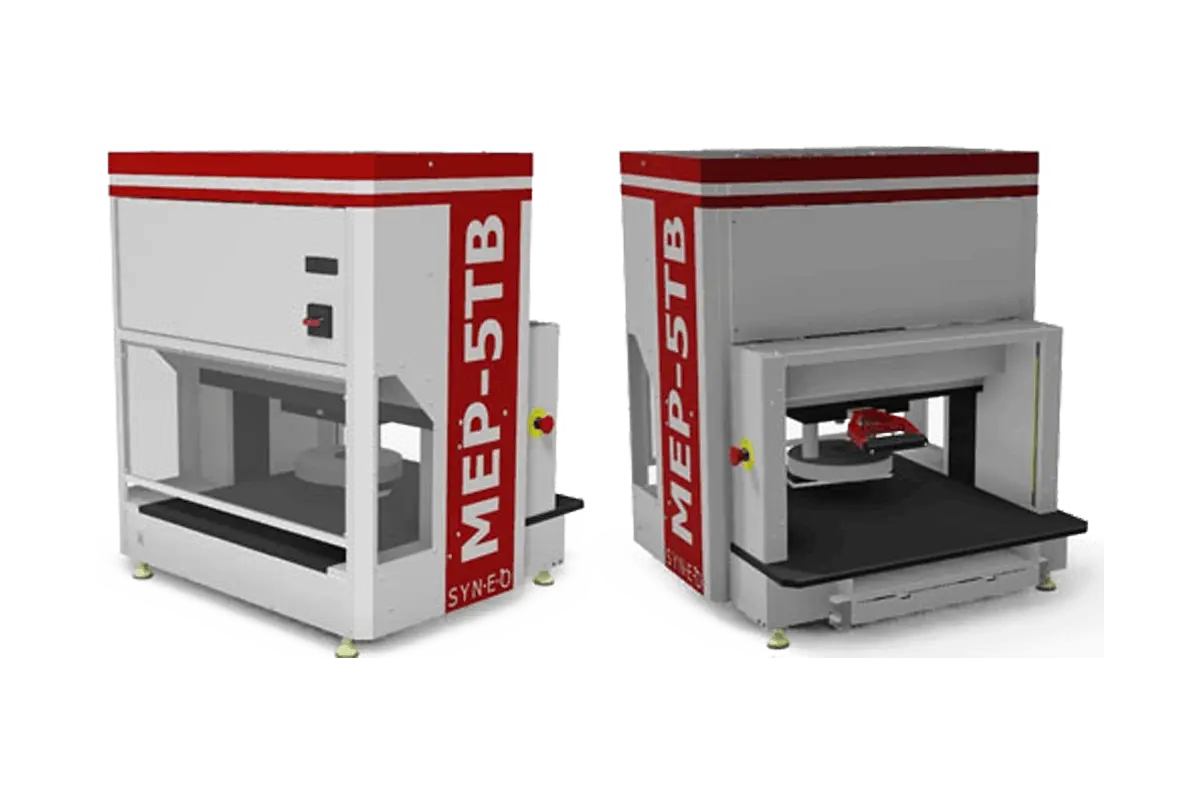

Parse the Event Log of SYNEO MEP-5TB, repackage the parsed strings, and send the string data to an HTTP server.

2023

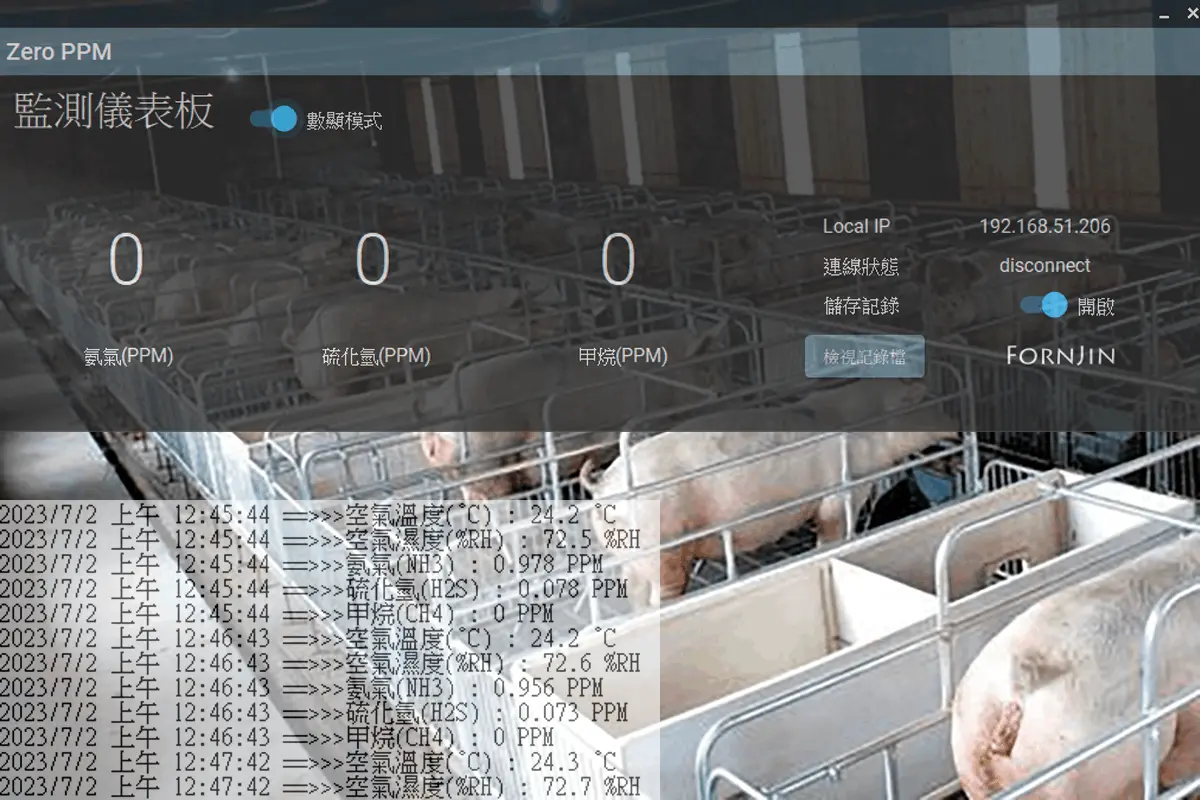

For the detection and warning of hazardous gases (hydrogen sulfide, ammonia, methane) in pig farms, using specialized LED spectral for decomposition.

2023

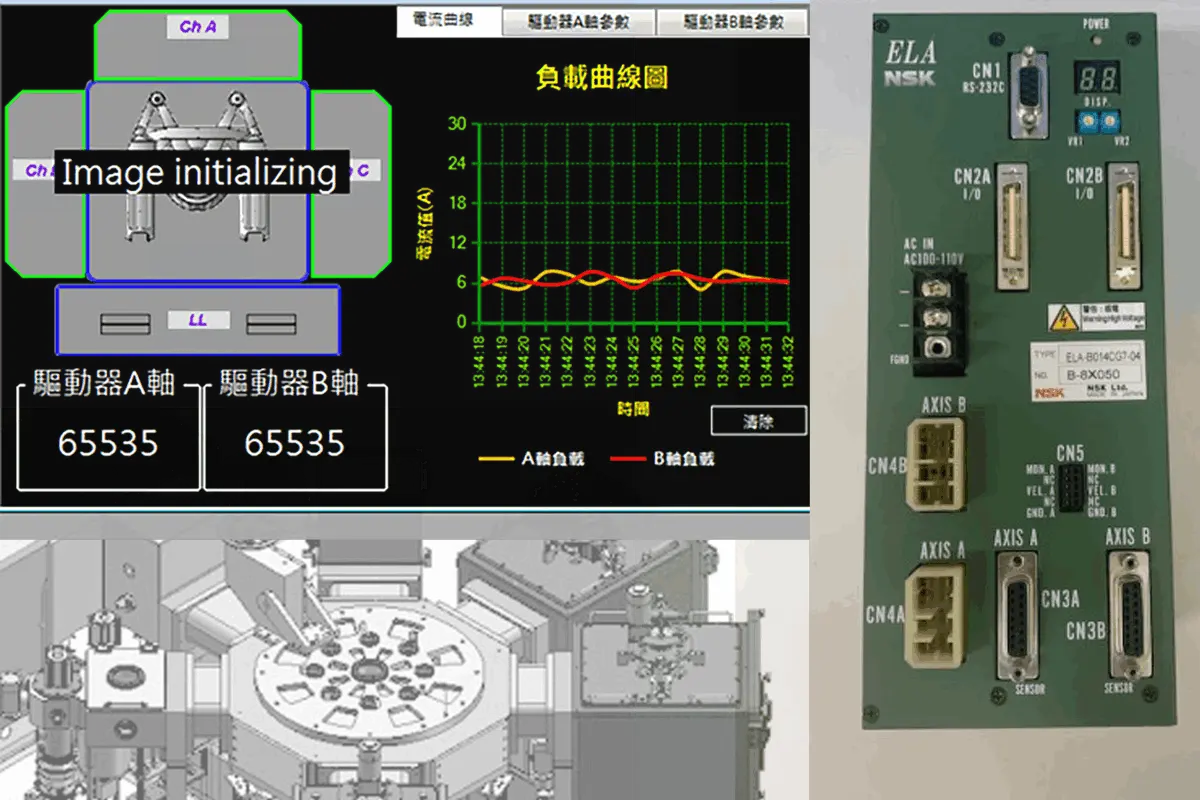

Monitoring and data logging of the driver and motor using external sensors and the driver's own axis position data.

2022

for the insufficient barcode functionality of the equipment, an external barcode reader is installed, utilizing SMEMA control to prevent production anomalies.

2022

For the REFLOW oven equipped with the KIC 24/7 furnace temperature monitoring system, an external barcode reader is installed, utilizing SMEMA control to prevent production anomalies.

2022

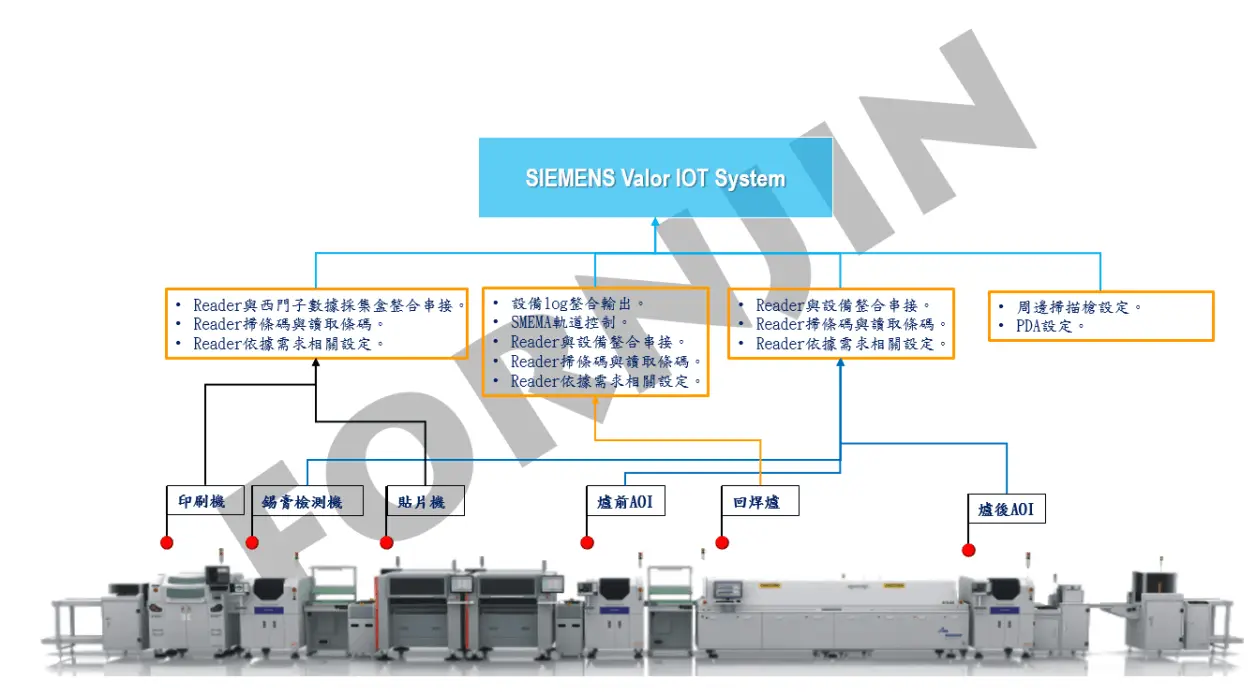

Addressing incomplete hardware integration with SIEMENS Valor, providing ample integration experience to collaboratively enhance the setup.

2022

To address the complexity of the equipment's native system operation, query database data and use external communication methods to quickly switch Laser Maker settings.

2021

For the REFLOW oven equipped with the VCAM 24/7 furnace temperature monitoring system, an external barcode reader is installed, utilizing SMEMA control to prevent production

2021

For older equipment lacking a barcode reader, install an additional barcode reader and utilize SMEMA to control process actions.

2021

For older equipment without manufacturer support, assist in rebuilding the operating system and refurbishing the computer host.

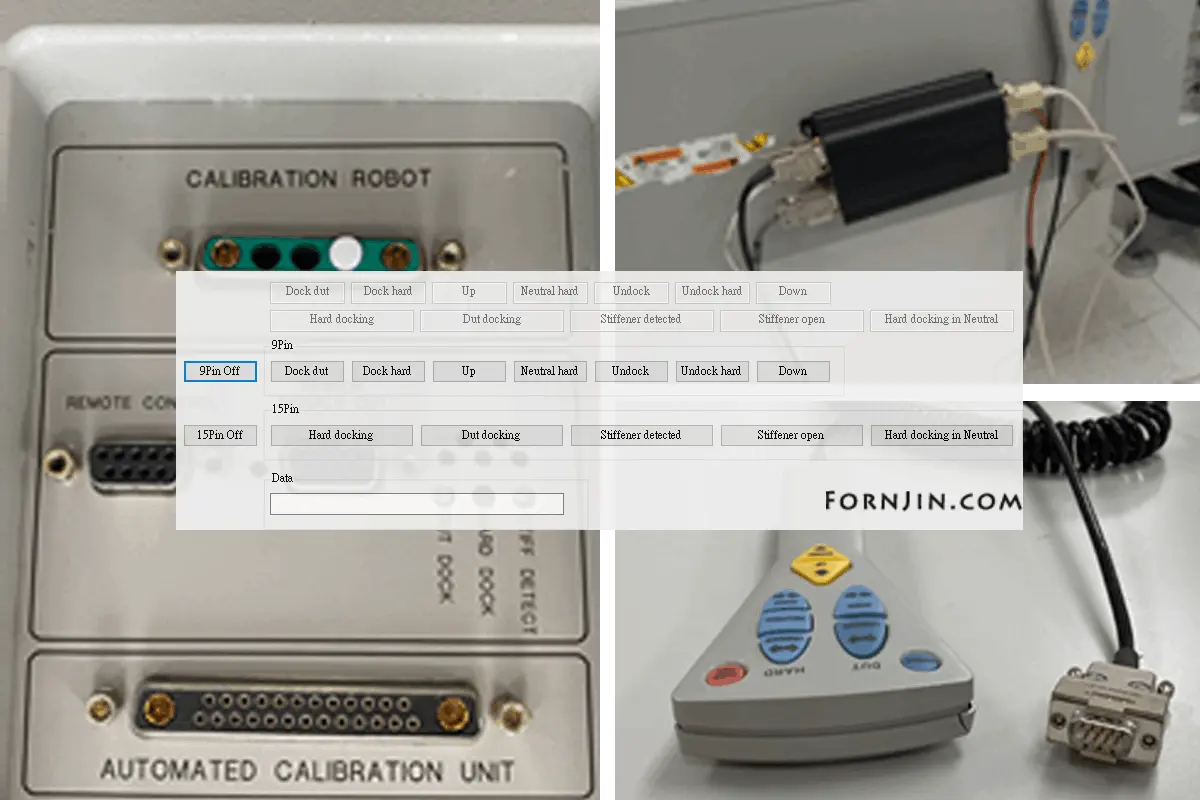

2020

For outdated devices lacking IoT capabilities, inject new remote control functionalities.

2020

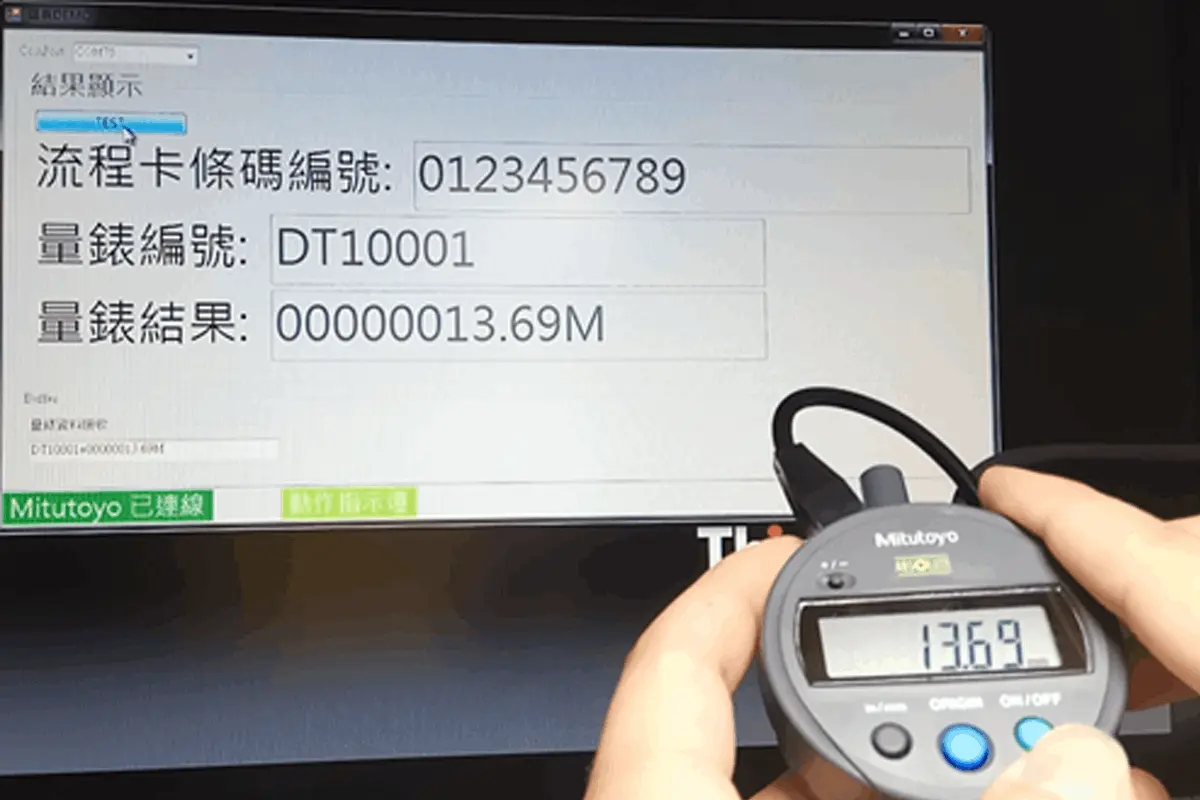

Modification of Mitutoyo micrometer with external wireless communication.

2020

The original OMRON barcode controller is missing, preventing installation of a barcode reader. Custom development of a barcode controller is required.

2020

For the REFLOW oven equipped with the ESAMBER 24/7 furnace temperature monitoring system, an external barcode reader is installed, utilizing SMEMA control to prevent production